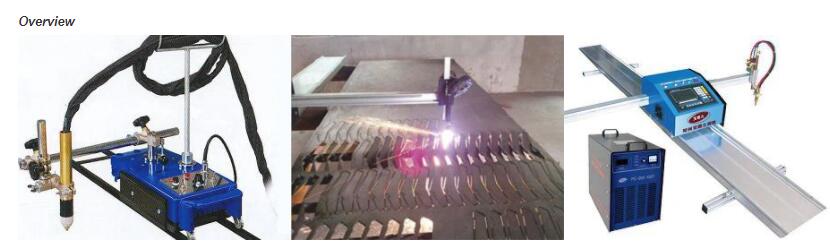

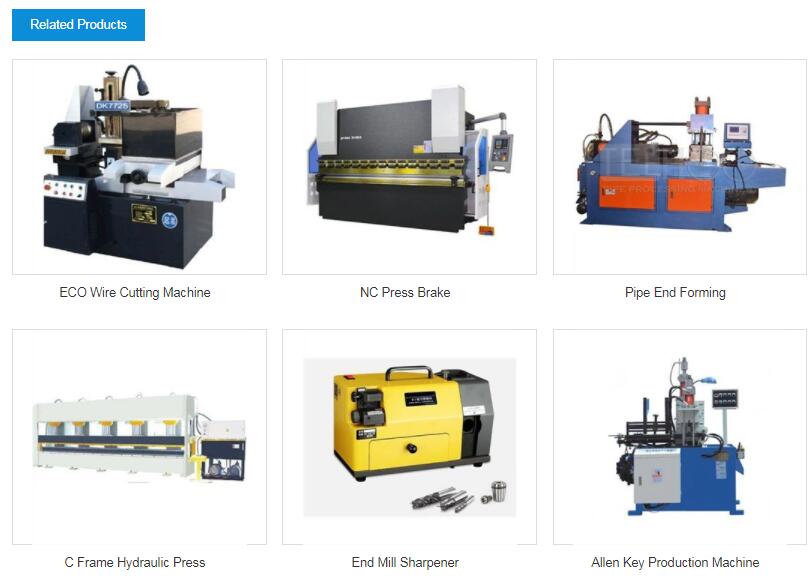

Plasma arc cutting is the use of high temperature plasma arc heat to make the workpiece incision metal local melting

(and evaporation), and by high-speed plasma momentum to eliminate the molten metal to form the incision of a processing method.

Plasma arc cutting is the use of high temperature plasma arc heat to make the workpiece incision metal local melting

(and evaporation), and by high-speed plasma momentum to eliminate the molten metal to form the incision of a processing method.

Plasma cutting with different working gas can cut all kinds of oxygen cutting difficult to cut metal, especially for

non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel) cutting effect is better;

Its main advantage is that when cutting the metal thickness is not large, the plasma cutting speed is fast,

especially when cutting ordinary carbon steel sheet, the speed can reach 5~6 times of oxygen cutting method,

the cutting surface is smooth, the thermal deformation is small, less heat affected zone.

Plasma cutting machine is widely used in automobiles, locomotives, pressure vessels, chemical machinery,

nuclear industry, general machinery, engineering machinery, steel structure, ships and other industries.

Hot Tags: plasma cutting, suppliers, manufacturers, customized, Laser Cladding, Hydraulic Cold Extrusion Press,

CNC Press Brake machine, adjustable wrench machine, pliers grinder, CNC Drilling&Tapping Center

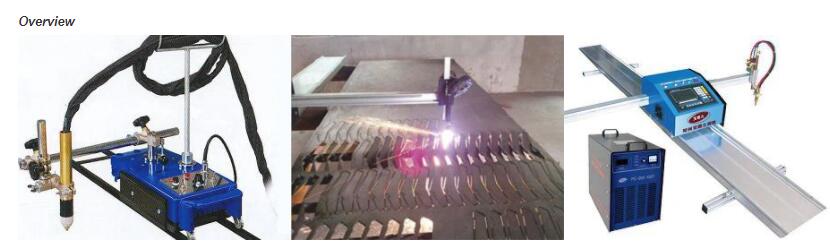

Machine Feature

1. The machine adopts the host system (computer host) produced by Sino-US joint venture, the transmission

rail made in Taiwan, the gas solenoid valve of Italy origin, approved by the United States UL

Taiwan switching power supply, German nesting software, all hardware and software are the best configuration of similar products.

2, The operation is simple and convenient and can improve the utilization rate of steel: not only can

the simple graphics directly manual programming on the system host video, but also can be randomly

presented by the nesting software for any complex graphics automatic nesting programming.

Using nesting software can not only carry out the conventional single workpiece cutting but also can be very

convenient for multiple workpiece coedge arrangement nesting cutting, series and bridging cutting (one-size-all).

Can improve the steel utilization rate of 1-5 percentage points.

3, Large program storage capacity: users can according to the need to store 1000 pieces of cutting workpiece drawings,

at any time to call the storage drawings for the workpiece cutting operation, save the trouble of drawing and input drawing repeatedly.

4, High cutting accuracy: cutting 500mm x 500mm square workpiece diagonal length and the diagonal length of the drawing error ≤ 1mm.

Cutting section roughness reaches, cutting back does not produce slags.

5. Plasma arc cutting and gas flame cutting can be selected according to customer needs.

When plasma cutting is selected, the machine is equipped with automatic arc pressure adjusting system and initial arc positioning

device to ensure continuous arc in the cutting process, and to ensure that the arc is 100% stable when plasma cutting begins.

6. The lifting system of the cutting torch (cutting gun) adopts the mechanical structure of the screw rod and is equipped with the

anti-cutting gun bump device to ensure the stable operation of the cutting gun and avoid the damage caused by the collision of the cutting gun.

7, The base adopts the whole steel annealing treatment, precision machining molding, to ensure stable and reliable operation

For big order or customized order, Pls feel free to contact service@vozop.com

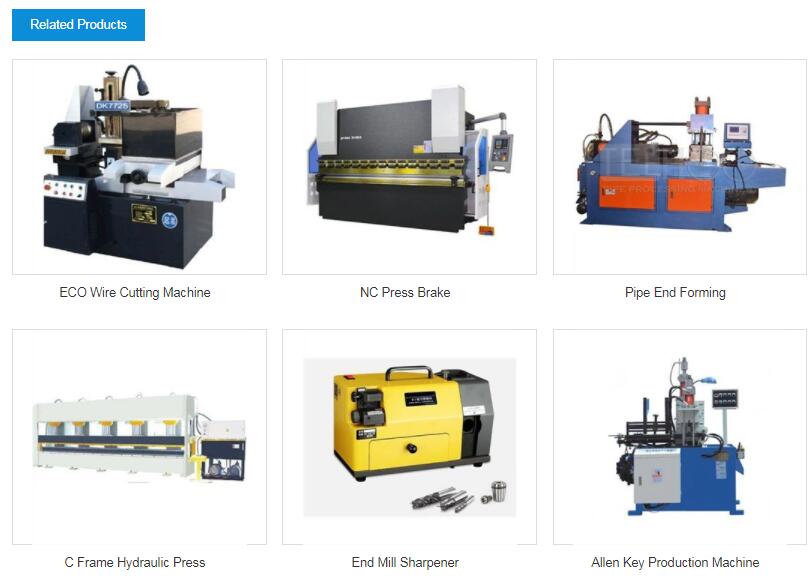

Vozop.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries,

like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc.

In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.