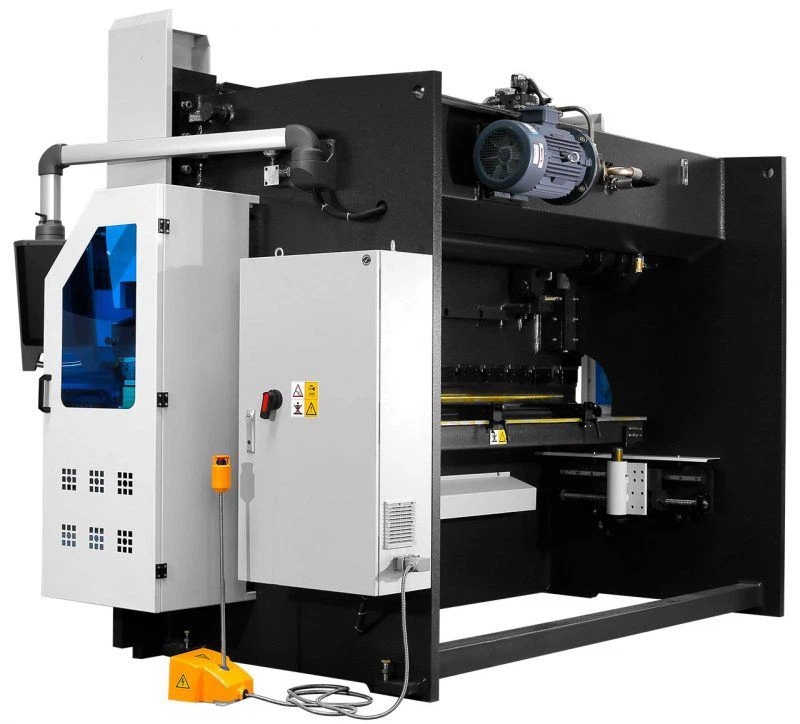

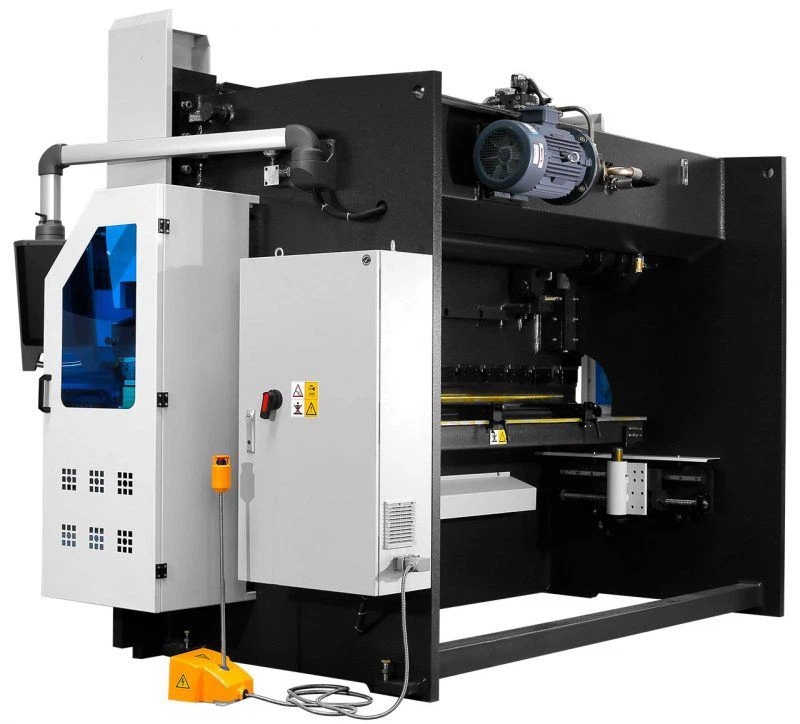

Adjustable torsion axis synchronization design, high quality hydraulic system, high precision back gauge structure.

Economic type NC Press Brake

Hot Tags: nc press brake, suppliers, manufacturers, customized, Conveyor Face Polishing Machine, Tap Sharpener,

Automatic Visual Laser Marking Machine, rod grinding machine, tap grinder, pipe cutter

Machine Feature

● Rack machining

The bending machine frame is integrally processed by a large floor boring and milling machine.

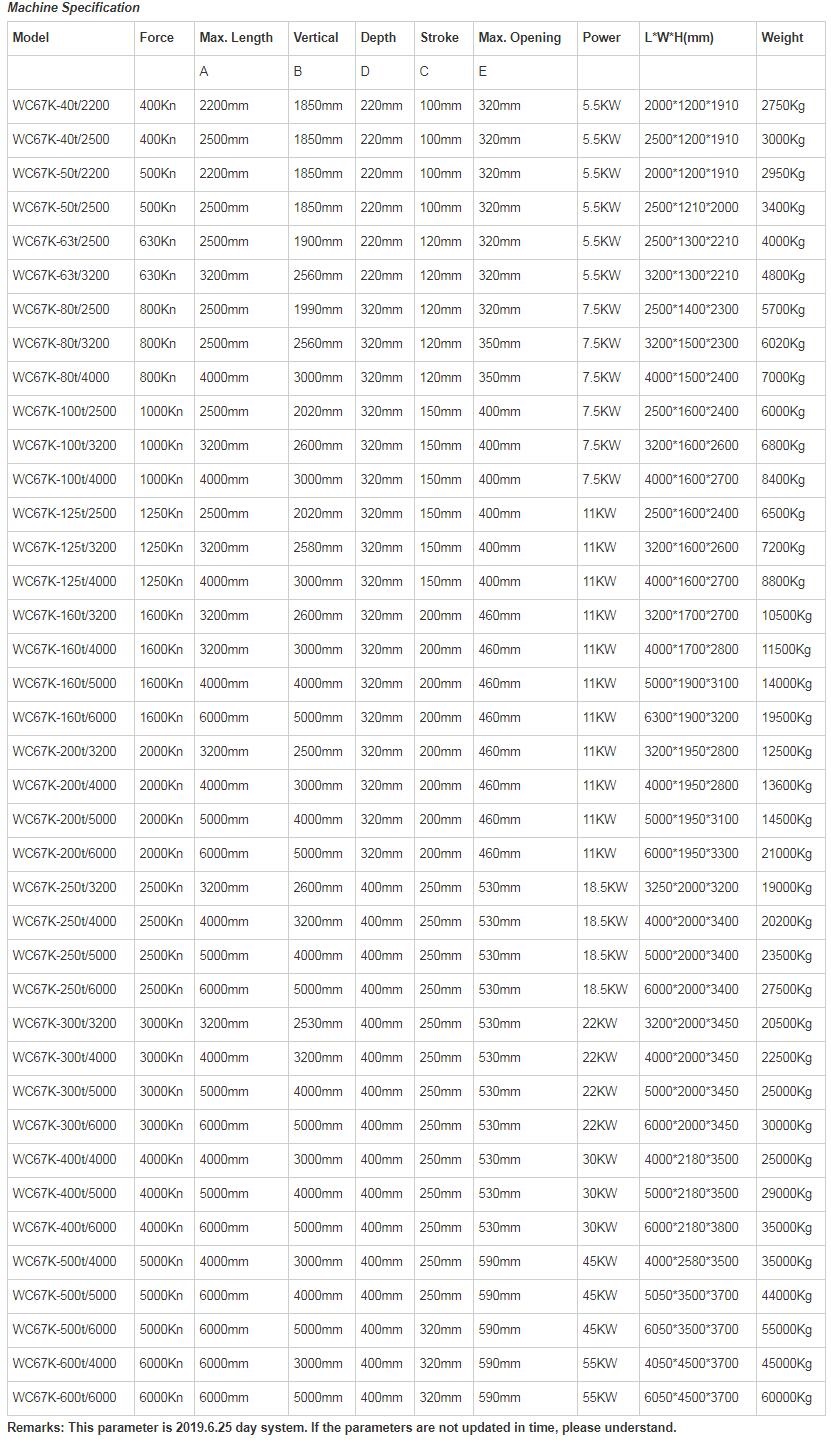

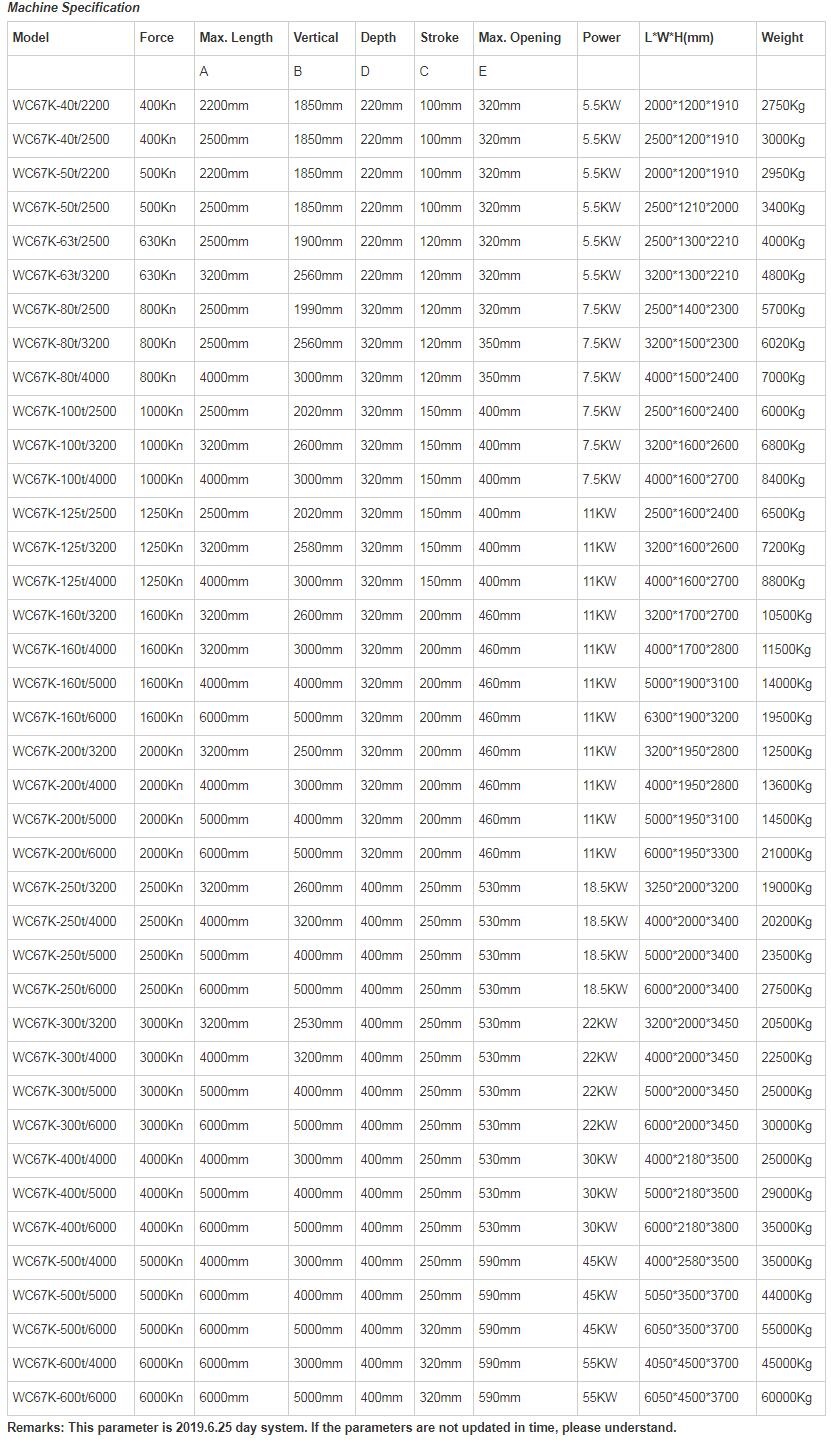

● Upper and lower mold standard segment

The user can customize the mold segments 10, 15, 20, 30, 50, 100, 300 (cm).

● Professional CNC system

Use ESTUN or DELEM brand CNC system for users to choose.

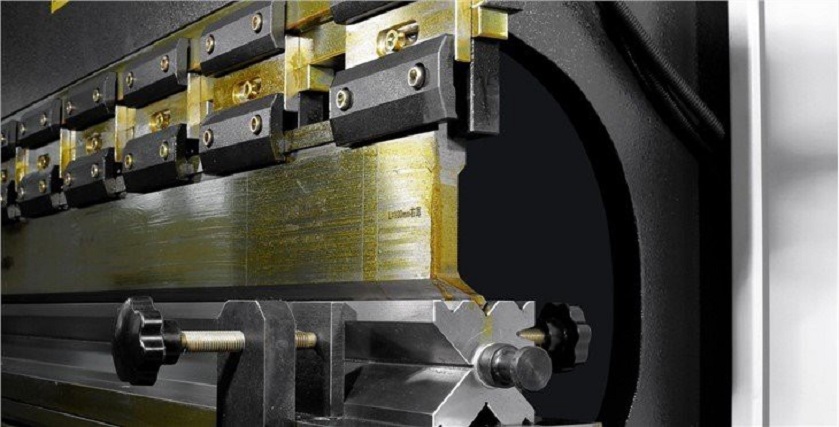

● The height of the finger can be adjusted manually

The height of the finger is designed from the overall adjustment, and the height of the finger can be adjusted manually.

● Basic fully functional hydraulic bending machine

Adjustable torsion axis synchronization design, high quality hydraulic system, high precision back gauge structure.

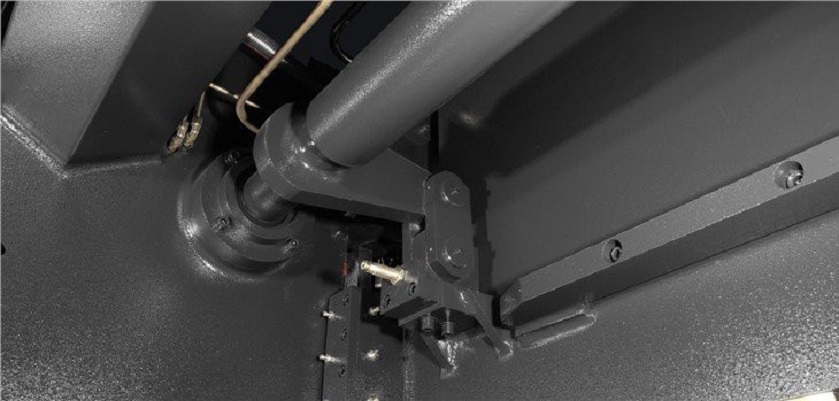

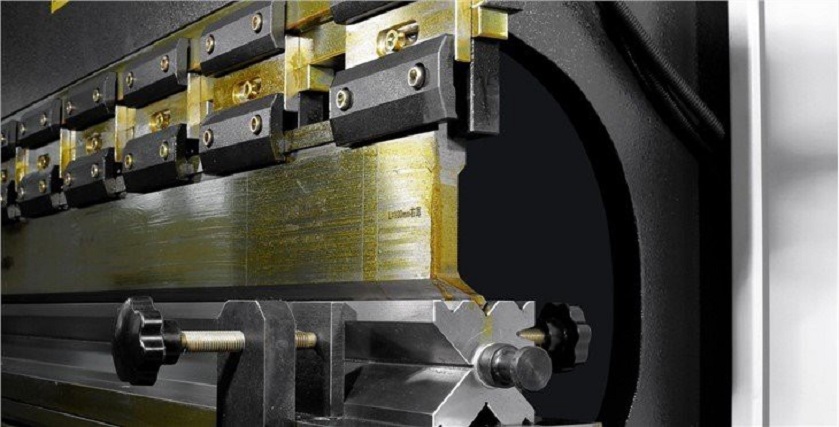

● High quality torsion shaft synchronization structure, high shaft strength and good elasticity

The shaft body adopts the traditional forging and tempering process, which has high strength, good elasticity and adjustable design.

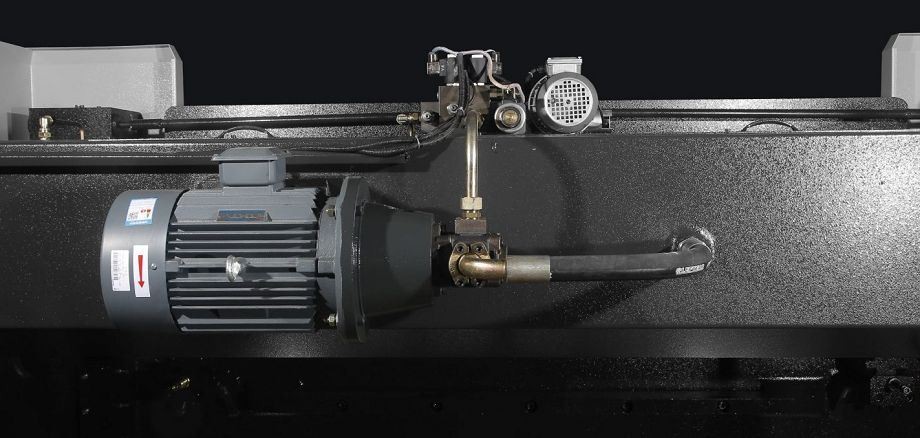

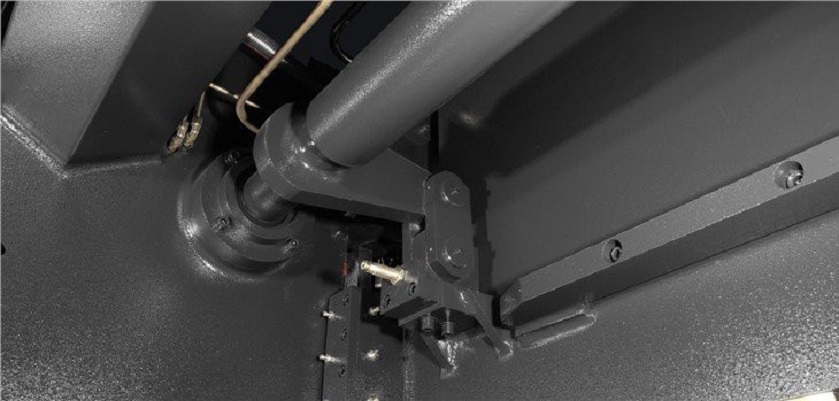

● Premium hydraulic system for durability

With Siemens motors as the main source of power, Sunny pumps and premium hydraulic valves for long-lasting hydraulic power.

● High quality forging die with high hardness and good toughness

Using the traditional forging tempering process, the bubbles in the steel material are removed, and the overall hardness is improved by heat treatment.

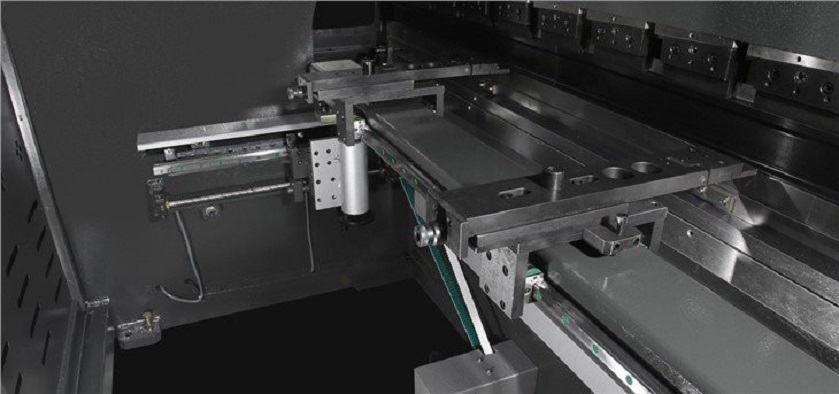

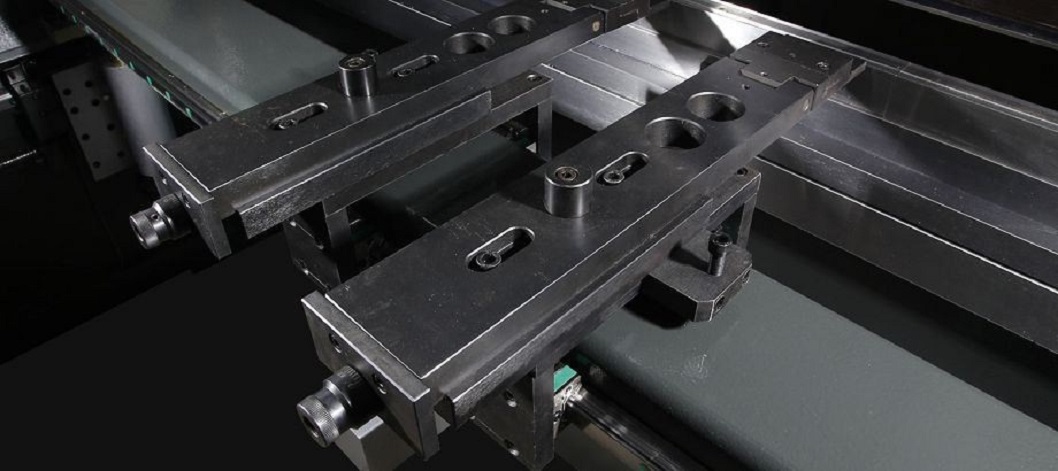

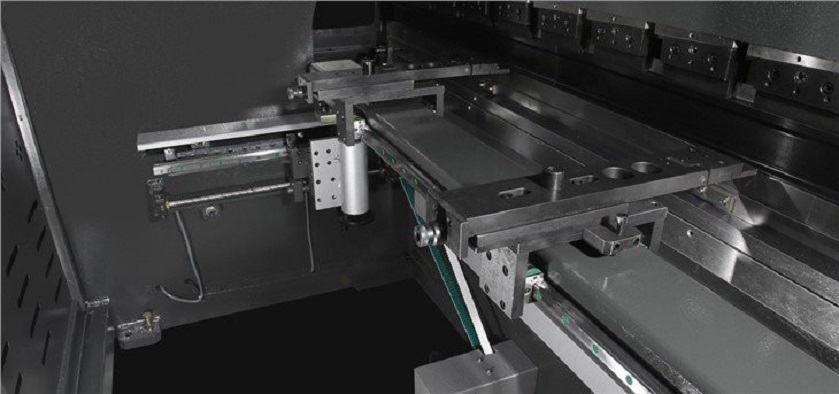

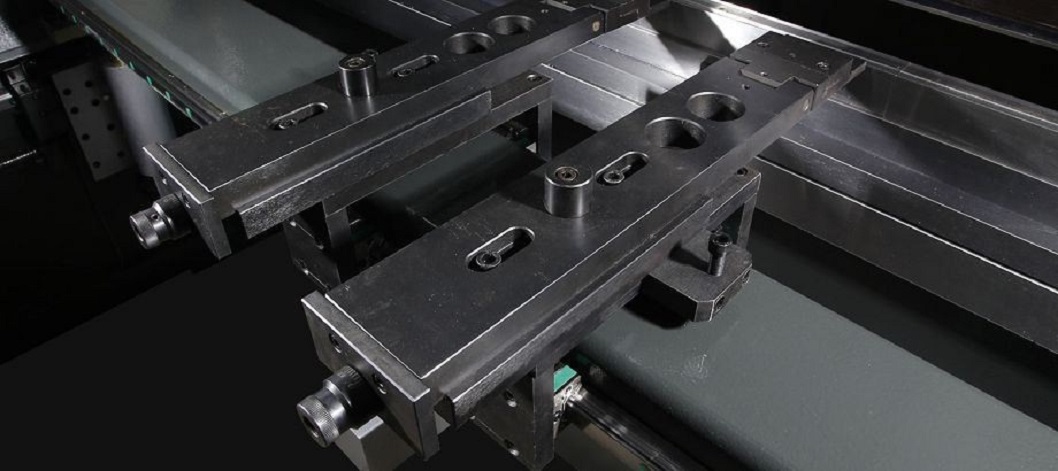

● High-strength backstop structure

The back gauge is welded by steel structure and has high rigidity. It is driven by AC motor, ball screw and linear

guide to ensure high precision operation. The four-corner mounting set screws can be quickly adjusted.

● (R-axis) beam height can be adjusted manually

The back gauge beam is made of square tube and has high rigidity. Engineers designed adjustable

linkages to achieve overall reduction or elevation of the finger.

● High precision and fast back gauge structure (optional)

The back gauge is welded by steel structure and has high rigidity. It is driven by servo motor, ball screw and linear

guide to ensure high precision operation. The finger frame has high parallelism and quick adjustment on the

double linear guide. Features. The four-corner mounting set screws can be quickly adjusted.

● Manual mechanical deflection compensation (optional)

Manual adjustment of deflection compensation is straightforward and has a digital display.

For big order or customized order, Pls feel free to contact service@vozop.com

Vozop.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries,

like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc.

In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.