Electromagnetic induction heating comes from Faraday's discovery of electromagnetic induction phenomenon, that is,

alternating magnetic fields in the conductor to produce induced current, resulting in conductor heating.

Overview

Electromagnetic induction heating comes from Faraday's discovery of electromagnetic induction phenomenon,

that is, alternating magnetic fields in the conductor to produce induced current, resulting in conductor heating.

Application

Medium frequency induction heating machine is suitable for large workpiece heat treatment and quenching,

annealing, induction welding and diathermic hot forging, can be customized according to customer requirements

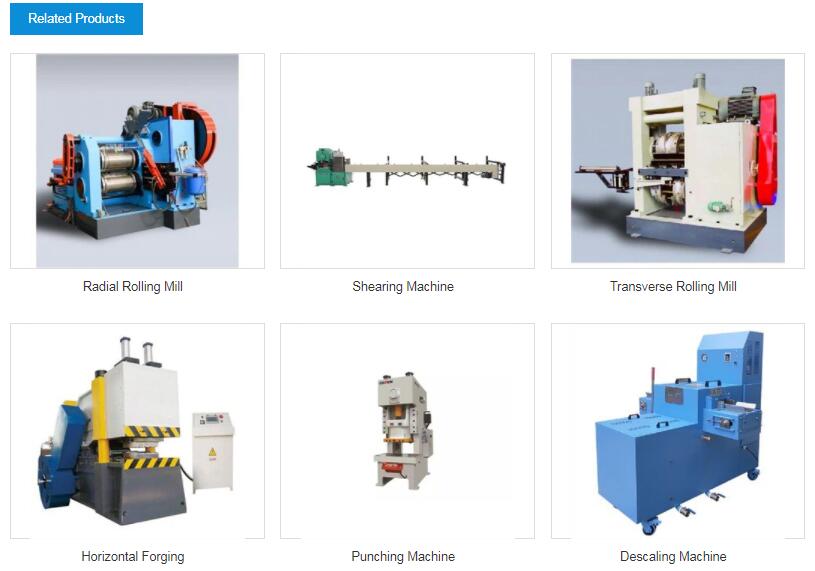

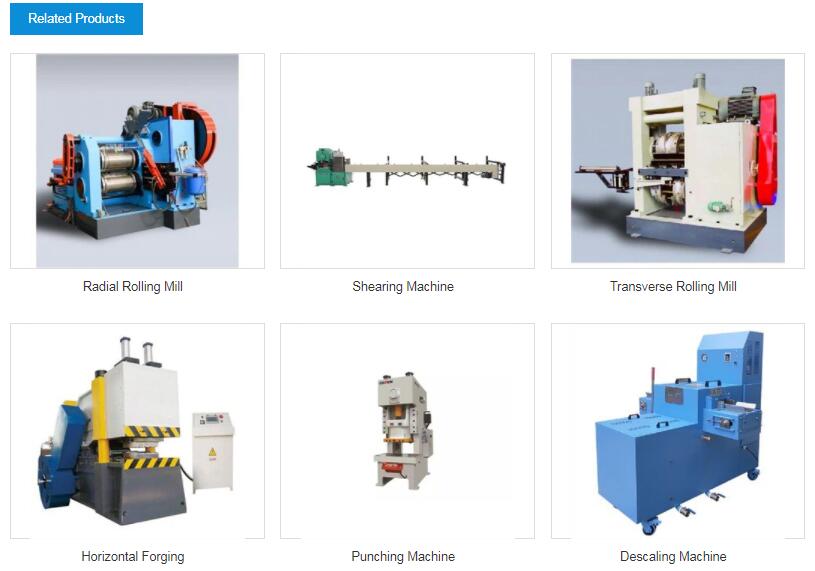

Hot Tags: induction heating machine, suppliers, manufacturers, customized, fanuc tapping center,

Metal Sheet Shearing, Plasma Cutting, shearing cutting machine, wire edm machine, hydraulic shearing machine

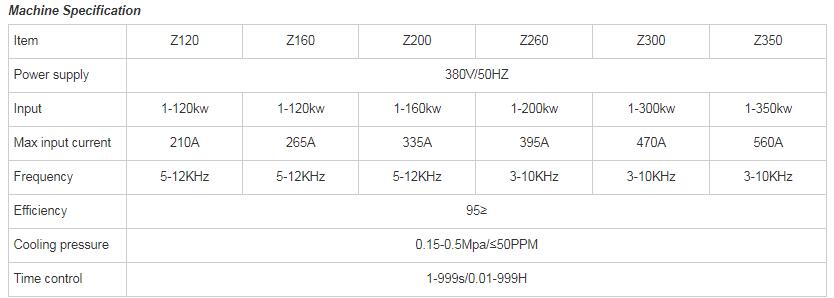

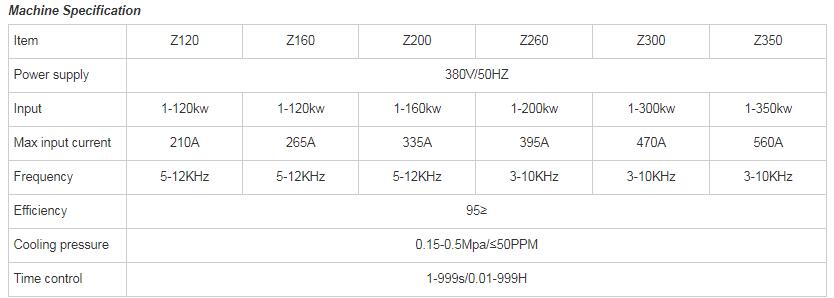

Machine Feature

1. High efficiency and energy saving, rapid heating using internal heating method, that is, through electromagnetic induction

to make the metal tube inside the cylinder itself heating, the average preheating time than the resistance ring heating method

is shortened by 2/3, at the same time the thermal efficiency of more than 95%, the power saving effect can reach 30%-70%.

2. The heating part adopts special cable structure, which will not generate heat itself, and can withstand the temperature

above 500℃. The service life can reach more than 5 years, and there is basically no maintenance cost in the later period.

Because the electromagnetic heating is through the electromagnetic induction to make the cylinder automatic heating,

the heat utilization rate of more than 95%, can fully and evenly to heat the raw material, so as to improve the quality of products.

3. Reliable operation, controllable and adjustable host adopts the most advanced industrial board, micro-electronic control,

multi-channel intelligent closed-loop system and perfect protection function, which can effectively avoid the aging

phenomenon of the host and fully guarantee the long-term safe and stable operation of the equipment.

4. Improve the working environment, the surface temperature of the equipment, human body can touch,

greatly improve the working environment of the production site, effectively improve the enthusiasm of workers,

reduce the cost of traditional cooling facilities.

In line with the "people-oriented" concept, to create a more green, energy saving, safe, comfortable production environment.

For big order or customized order, Pls feel free to contact service@vozop.com

Vozop.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries,

like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc.

In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.