FAQ

How to operate horizontal broaching machine?

1. Lubricate according to the lubrication requirements before work to prevent grinding accidents.

2. Check whether the position of each operation handle is correct, and the stopper of each stroke limit must be firm.

3, Start the oil pump, first pull rod air travel several times to exclude the air in the hydraulic system,

and check whether the limit switch is good, the pressure gauge is normal, check whether the hydraulic pipe,

oil pump oil, pull rod, screw, guide rail is brushed.

4, In the work of the tool must be firmly installed, loading and unloading tools, workpiece to prevent damage to the machine tool.

According to the processing of the workpiece, adjust the working speed of the pillow and the position of the return and reverse collision and tighten it.

5, In the work of fast tool alignment, in the cutting process, the tool is not allowed to stop before withdrawing from the workpiece.

Horizontal broaching machine is suitable for all kinds of mechanical parts of the disk, sleeve, ring hole keyway,

special-shaped hole and spiral flower between the geometric shape of finishing.

Overview

Horizontal broaching machine is suitable for all kinds of mechanical parts of the disk, sleeve, ring

hole keyway, special-shaped hole and spiral flower between the geometric shape of finishing.

Widely used in automobiles, motorcycles, agricultural machinery, textile machinery, band sawing machine,

bench drill, power tools, cutting tools, motor, reducer, water pump, air conditioning and gear, sprocket,

worm gear and other manufacturing industries, suitable for mass production production efficiency is

far higher than milling machine, slotting machine and planer.

It has the characteristics of high precision and high efficiency.

This series broaching machine is simple in structure, easy to maintain and easy to operate.

Because broaching speed is small, cutting temperature is low, tool wear is slow, so broach durability is high.

This machine tool has two kinds of automatic circulation and semi-automatic circulation.

We can also customize different types of hydraulic equipment according to customer requirements.

This machine is a high-precision equipment for broaching inner hole, square hole, single key, spline,

inner tooth, inner four Angle, hexagon, octagonal bearing hole of mechanical parts with geometric shape.

High efficiency, high precision, simple operation, low labor intensity, suitable for mass production.

Hot Tags: horizontal broaching machine, suppliers, manufacturers, customized, double column gantry center,

big vertical machining center, Laser Cutting, horizontal milling, cnc wire cut machine, Pipe Cutting Machine

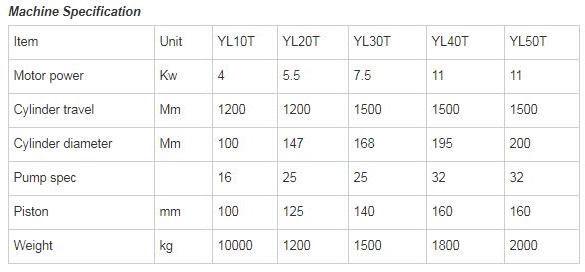

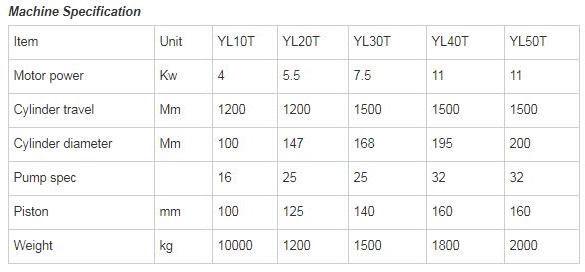

Machine Feature

1. The machine bed has a great improvement, using coaxial machining technology, machining accuracy is quite high.

2. Hydraulic oil supply system adopts axial high pressure variable piston pump, and broaching speed can be adjusted stepless.

Different diameters and different lengths of various specifications of broach can achieve the working state.

3. The key parts of the machine cylinder, using high quality thick wall seamless steel pipe, piston rod after tempering,

high frequency, burning process processing and manufacturing, using high wear-resistant bushing and high wear-resistant

sealing components of high quality cylinder, to provide strong power for the machine.

4. The hydraulic control system adopts the differential circuit, and increase the back pressure control, the use of broaching

machine special solenoid valve to greatly improve the efficiency of the machine, the operation is more stable.

5. The point distribution system is designed on the front of the machine tool, which is more convenient for electromechanical linkage operation.

6. Due to the use of the above advanced technology and processing technology, compared with the old machine tool,

the machine can save more than 50% electricity, improve the work efficiency of more than 30%.

For big order or customized order, Pls feel free to contact service@vozop.com

Vozop.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries,

like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc.

In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.