The line cutting machine is mainly composed of three parts: machine tool, numerical control system and high frequency power supply.

Overview

The line cutting machine is mainly composed of three parts: machine tool, numerical control system and high frequency power supply.

The numerical control system is composed of single chip microcomputer, keyboard and frequency conversion

detection system. It has the main functions of gap compensation, linear interpolation, circular interpolation,

automatic processing of broken wires, etc.

Can cut materials, such as high strength, high toughness, high hardness, high brittleness,

magnetic materials, as well as precision and small and complex shape parts.

Wire cutting technology, wire cutting machine tools are widely used in all walks of life.

Hot Tags: eco wire cutting machine, suppliers, manufacturers, customized, thread rolling, hand tapping machine,

Conveyor Face Polishing Machine, CNC Hand Tools Polishing Machine, hammer polishing machine, water pump thread turning machine

Machine Feature

1.Large travel , High cutting speed.

2.Four axes independent UV work.

3.Work pieces to 600mm thick.

4.Taper angles up to ± 30°.

5.Standard model is equipped with ± 3° taper attachment.

6.Molybdenum wire diameter 0.12~0.22 mm (down to 0 .08mm).

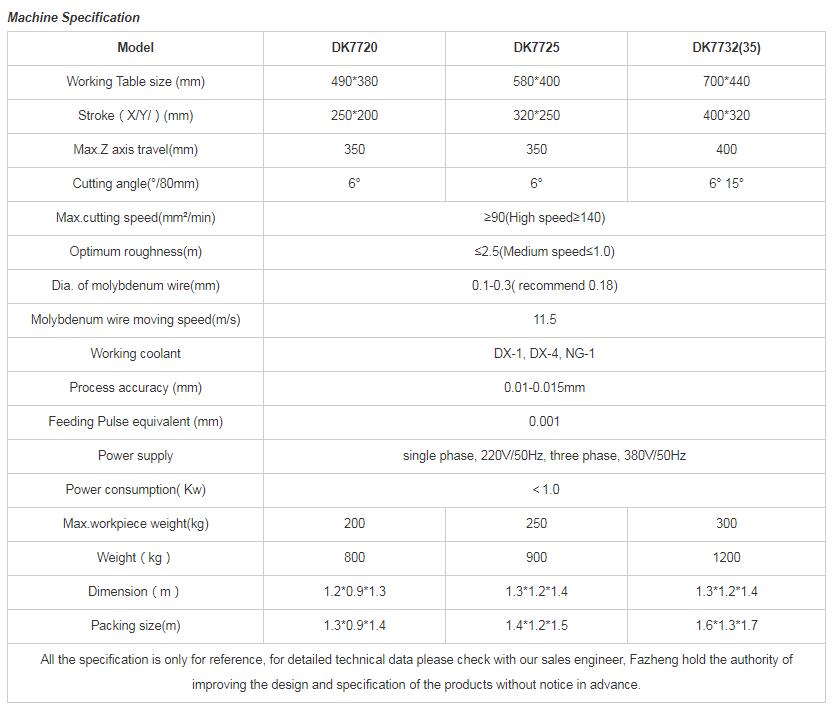

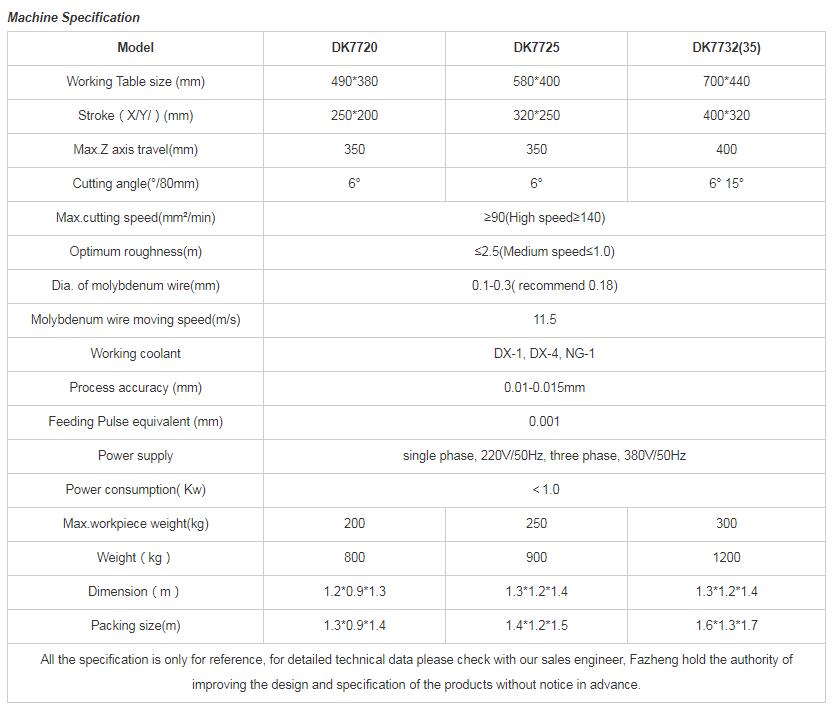

7.Accuracy: 0.015mm, even 0.01mm.

8.Roughness: Ra 1.6-2.5 µm.

9.Low consumption, material saving.

10.Closed loop glass scales on all four axes for positional accuracy of 0.005mm.

11.Advanced CAD/CAM software with file transfer and translation capabilities.

12.High cutting speed modular is optional.

For big order or customized order, Pls feel free to contact service@vozop.com

Vozop.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries,

like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc.

In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.