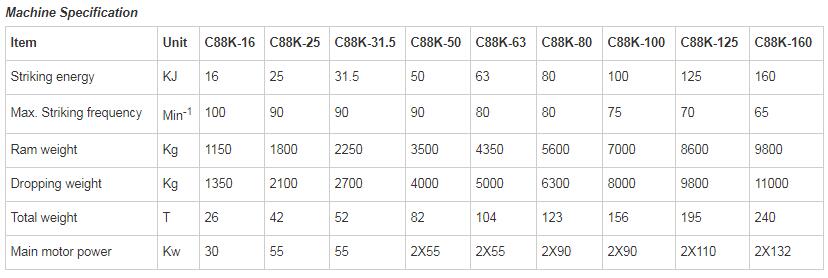

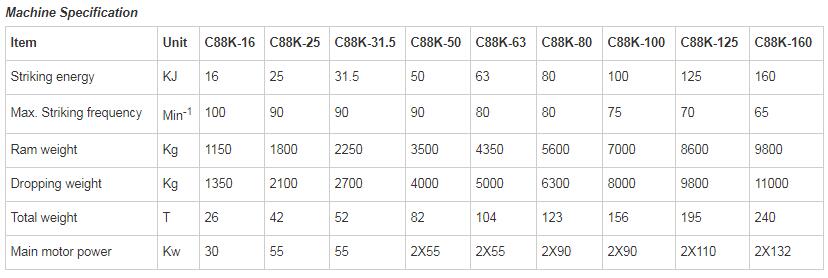

It uses one-piece U-frame casting steel hammer body, with max. striking energy from 16kJ to 160kJ.

That frame is wide application and standard one.

Overview

It uses one-piece U-frame casting steel hammer body, with max. striking energy from 16kJ to 160kJ.

That frame is wide application and standard one. Hammer body is cast as one piece to avoid columns

and anvil connecting, reduce separated hammer body contacting surface wear, improve body strength,

and make this hammer afford off center forging force.

Its guiding is using the steel X-shape guide rails fixed in the hammer body inner face by bolts,

with three inserted locating face to avoid bolts receive force. Imported locking washer is used to avoid bolts lose.

Extending line of contacting surface of guide rails and ram crosses on the ram center, which cannot effect guide

clearance due to heating, and clearance between ram and guide rails can be adjusted to be small to assure die

matching. And this guide rails lubrication is automatic and once forging is stop, lubrication will be stop.

Its striking system is with big ram structure, which can make sure striking energy when striking speed is down.

And longer ram guiding can improve hammer working accuracy.

Its control system can make sure striking energy controlled and program striking realized, avoid vibration and

noise arising from surplus energy. Program automatic control system can control each striking energy and steps

according to requirement, which make striking system vibration and noise reduce more, lower requirement for

operator, get stable forging accuracy, improve hammer running reliability and die life. Striking program is easy to

input, no need skilled computer engineer, even semi-skilled worker is OK. There is malfunction display window on

this control system. Once problem, it will be easy and quick to find malfunction reason through this window,

and then deal with it at once to short maintenance time.

Special designed die automatic lubrication, blank convey system, ejector and scale removing system are for

customer to choose. They can be linked to hammer through program to realize die lubrication locating, timing,

quantifying control, to improve its productivity and reduce labor intensity.

Application

Hot Tags: CNC forging die hammer, suppliers, manufacturers, customized, broach machine, rod cutting machine,

high speed milling, laser hardening applications, vibratory polishing machine, special purpose turning machine

Machine Feature

1.Program control, numerical input, simple operate;

2.High integrated hydraulic control system, accumulator fixed directly on main valve block without any pipe connecting,

improve hydraulic system efficiency and easy for maintenance;

3.Advanced taper valve control, fast response, good sealing and not easy to inner leakage;

4.One-piece casting steel U-frame, radial wide guide rails, to get stable and high ram guiding accuracy;

5.Touch screen man-machine interface and automatic malfunction diagnosis and alarm, easy for machine operation and maintenance;

6.Digitized and exacted controlling striking energy, avoid surplus energy harm during striking;

7.Three inserted locating faces to avoid bolts receive force and imported locking washer is used to avoid bolts lose.

8.Fully hydraulic driving system, avoid oil and air mixing;

9.Swaying combine oil cylinder and thin piston rod flexible design;

10.High and low pressure double anti-leakage design;

11.Slow up and down in the case of releasing hydraulic system pressure to make die changing safety;

12.Ram buffer is inner hydraulic buffer, to make sure safety and effective;

Optional machine

1.Special designed die automatic lubrication, blank convey system, ejector and scale removing system are for

customer to choose. They can be linked to hammer through program to realize die lubrication locating, timing,

quantifying control, to improve its productivity and reduce labor intensity.

2.Remote monitor system can save maintenance engineer to user’s workshop time and cost. It not only save large

labor and resource cost, but also supply fast service to customer to reduce loss arising from hammer stopping.

For big order or customized order, Pls feel free to contact service@vozop.com

Vozop.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries,

like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc.

In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.